How to Reduce Your Warehouse Inventory?

Employee-related warehouse stock (e.g., PPE, personal protective equipment, tools and equipment, workwear), along with consumables and auxiliary materials, are essential in every facility. Without them, operations often cannot continue, leading to downtime. On the other hand, such stock can occupy significant space and generate considerable costs. A great solution is optimizing warehouse processes using ASD Systems vending machines.

Minimum, Maximum, and Excess Inventory – What You Should Know

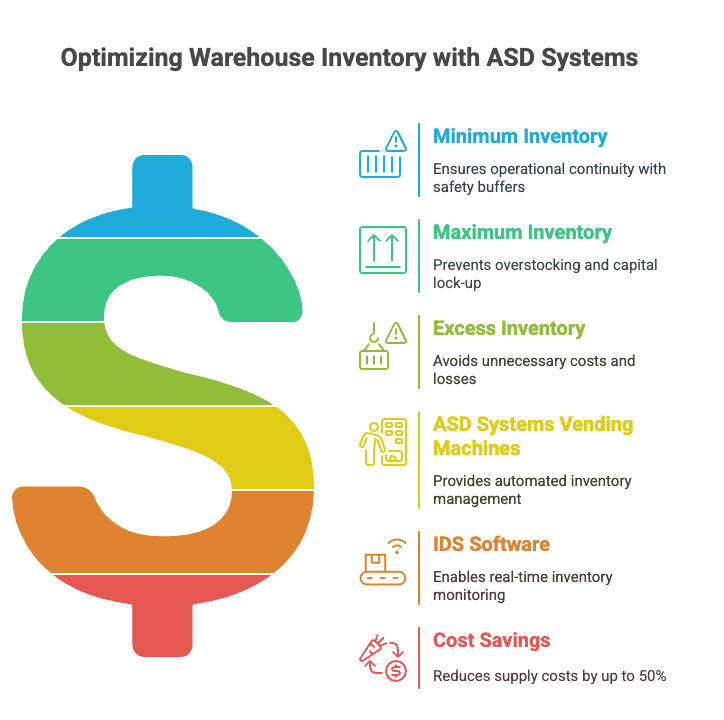

Maintaining the right inventory levels is a key part of managing both costs and available warehouse space. This is especially important for production, service, and logistics companies. Too little stock causes downtime, while too much leads to frozen capital and overfilled storage. Therefore, proper warehouse optimization and understanding concepts like minimum, maximum, and excess inventory are fundamental to establishing an effective inventory policy.

What is Minimum Inventory?

Minimum inventory is the lowest acceptable stock level that protects a company from running out of a given item. It’s especially important in cases of delivery delays or unexpected surges in usage. This acts as a safety buffer to ensure operational continuity and timely service delivery.

Falling below the minimum inventory level may lead to production stoppages and delays in fulfilling orders.

What is Maximum Inventory?

Maximum inventory sets the upper limit of how much stock should be held. This level is based on available warehouse space, product rotation rate, storage costs, and shelf life.

Keeping stock below this limit prevents overstocking, capital lock-up, and spoilage. Exceeding it raises storage and maintenance costs and risks material losses due to expiration.

What is Excess Inventory?

Excess inventory is when the quantity of stock exceeds both current demand and the maximum inventory level. It often results from ordering mistakes, poor demand forecasting, or lack of usage control. Sometimes it comes from a “just in case” approach.

The result is unnecessary costs, expired or obsolete stock, tied-up working capital, and greater risk of inventory-related losses.

To prevent these outcomes, it’s worth implementing modern storage systems and innovative logistics technologies, such as those offered by ASD Systems.

What Makes ASD Systems Vending Machines Unique?

ASD Systems vending machines are designed and manufactured in Poland and run on proprietary IDS software. They enable fast, affordable optimization of inventory and supply chain processes, especially for production, service, and logistics facilities.

The machines are adapted for dispensing a wide range of items — from PPE and safety gear to consumables, tools, and even office supplies.

Replacing a traditional warehouse (staffed by multiple employees for control, tracking, and distribution) with a network of vending machines can reduce supply costs by up to 50% and provide continuous, automated monitoring of all essential products that typically generate expenses and losses.

How It Works

Unmanned Distribution of Production and Employee Supplies

An entire warehouse stock can fit into a few vending machines. The compartments are configurable to match product type and quantity. This saves substantial space compared to traditional warehouses.

Each employee receives, for example, a proximity card, which they use to retrieve items. The machine identifies the user and allows them to select the required items in just a few seconds.

Machines are available 24/7, eliminating the need for multiple employees to manage supplies — in many cases, a single person can oversee the entire inventory system.

Material Usage Control

Depending on the machine model and software version, ASD vending machines offer various features:

- Labeling – Items can be tagged with information such as expiration dates or usage types. This encourages conscious and responsible usage, helping reduce consumption and generate savings.

- Returns – Employees can return used or partially used items. This gives inventory managers insight into usage patterns and allows for further optimization.

Full Control Over Minimum and Maximum Inventory

Machines can be connected to the company’s server via Wi-Fi, Ethernet, or GSM modem. From any device with internet access, inventory managers can use the IDS application to monitor inventory levels in real time.

- Alerts notify staff when items are running low.

- Refills are fast — thanks to drum scanning, the system shows exactly where and how many items to replenish.

Real-Time Inventory Access

The IDS app provides instant, live access to inventory status.

It shows what products are available, which items are in excess and don’t need replenishing, and which should be restocked soon due to supply chain risks.

Managers can categorize items accordingly and ensure continuity of operations.

Smarter Ordering Decisions

Managing inventory through the app improves efficiency and accuracy.

It saves time, eliminates manual entry errors, prevents downtime caused by stockouts, and supports data-driven ordering policies.

Managers know which products to reorder, which to scale down, and in what quantity – reducing waste and avoiding overstocking.

Restricted Access to Inventory

One of the biggest benefits of ASD vending machines is the ability to restrict employee access only to the items they actually need for their roles.

Employees can’t access everything — only what they are authorized to use.

This minimizes accidental or unauthorized withdrawals, prevents misuse of equipment, and limits loss or theft.

Withdrawal Limit

Each employee can be assigned withdrawal limits for specific items within a set period (e.g., per month). This enforces responsible usage and ensures that products are used for their intended purposes and over a realistic duration.

Such controls can reduce consumption by up to 50%, translating to significant cost savings.

Instant Inventory Reconciliation

Even a single person can manage the vending system efficiently.

The IDS system provides access to data, usage history, and automatically generates reports useful for departments like finance, purchasing, and controlling.

Employees can also tag their withdrawals to specific cost centers, departments, or projects, simplifying internal cost tracking and reporting.

FAQ

How can I reduce warehouse stock?

Place production and employee supplies in ASD vending machines. This reduces storage space, limits access, and enforces usage limits — cutting consumption and total stock volume.

How can I monitor warehouse stock?

With ASD Systems, inventory managers have full control and visibility. The app tracks product flow and usage by item and employee, making it easy to manage turnover rates and plan ahead.

How much can I save with vending machines?

Our data shows that using ASD Systems vending machines can reduce warehouse consumption and costs by up to 50%. It’s a financially smart and operationally efficient solution.