Which warehouse processes can be automated?

Warehouse process automation is a natural consequence of the ongoing digital transformation. Its primary goals are to increase company efficiency, enhance the effectiveness of operations, improve employee safety, and reduce labor costs. More and more companies are choosing modern solutions that streamline logistics processes. This article explains what and how you can automate – easily and cost-effectively, without the need for major investments or extensive employee training.

Logistics Process Automation – Warehouse 4.0

The fourth industrial revolution emphasizes the integration of machines with the Internet and information technologies. In logistics, shipping, warehousing, and transportation, this influence is visible through terms like “Logistics 4.0” or “Warehouse 4.0.” To remain both efficient and competitive in today’s market, automating warehouse and logistics processes is now essential.

Warehouse automation can be implemented at any stage of a company’s operations. Return on investment is typically achieved within a few years of making changes to warehouse logistics. It involves automating storage, order preparation, and shipment processes – but improvements can be rolled out gradually rather than all at once.

Automating Warehouse Processes

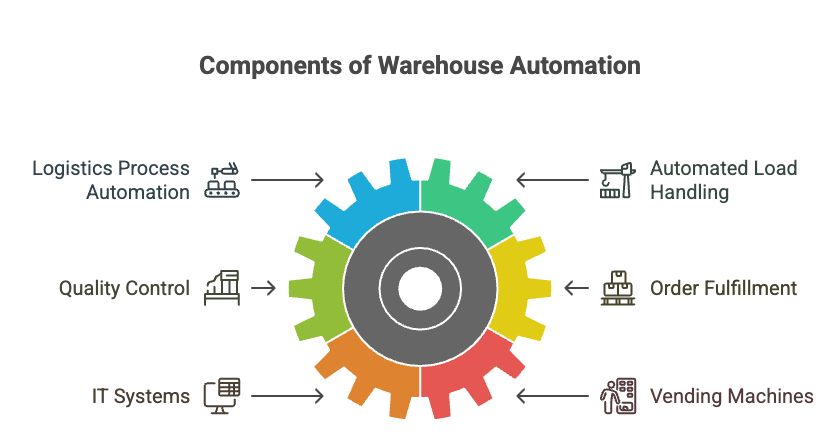

Key warehouse logistics processes suitable for automation include:

- storage, transportation, and placement of goods,

- order picking, packing, and fulfillment,

- inventory level control and material demand forecasting.

All these operations, whether in an analog or digital warehouse, are logistics-driven and can be automated.

Automated Warehouse: Load Handling

Goods handling (unloading, arranging, transporting) is a core automation area. Automated stacker cranes play a central role here. These machines load and unload goods from shelving systems (pallets, containers, bins, etc.) by moving along floor rails to specific locations.

The “brain” of a stacker crane is a microprocessor, enabling customized programming. Stacker cranes vary by load cycle time, payload capacity, fork length, rack depth, and mechanism type (grabber, fork, conveyor).

Best results are achieved by assigning one crane per aisle. Warehouses should also include additional transport systems such as conveyors (even for multi-floor transport or truck loading), rail-mounted trolleys, and shuttle carts. Properly deploying cranes and infrastructure elevates warehouse operations to a new level: faster, more efficient, and less prone to errors or downtime.

Automated Warehouse: Quality Control

Automation also includes verifying the quality of incoming goods. Stations integrated with lifts can automatically check the condition, size, and weight of items. These automated checks improve the detection of anomalies, reducing the risk of delays, errors, or complaints further down the supply chain.

Automated Warehouse: Order Fulfillment

Automated order prep includes wrapping and labeling pallets for dispatch. Instead of manual labor, manipulators can handle large or heavy loads more effectively. These systems relieve physical strain on staff and allow team members to focus on other tasks. In the long run, they help prevent injuries and reduce absenteeism.

IT Systems: Automation and Asset Distribution Control

Warehouse management systems (WMS) are essential for automating processes. One solution is the IDS software, which powers smart dispensing machines for warehouse use.

These systems require minimal manual input and provide full traceability of materials used daily by staff – tools, PPE, and consumables. WMS can monitor all logistics operations and are especially effective when managing diverse shipments from multiple sources.

Real-time, secure data flow enables efficient operations and helps avoid bottlenecks.

Vending Machines: Comfort and Cost Optimization

Warehouse performance depends heavily on task organization. Staff need access to consumables, tools, and safety items. Traditionally, this involves going to a storage point, collecting items, and having it logged manually.

Vending machines simplify this process – operational 24/7 without involving additional personnel. They log who took what and when, providing instant reports. This streamlines inventory control, curbs misuse, and reduces overhead. No more morning queues or assigning staff for distribution.

Organizing Work in the Automated Warehouse

Warehouses rely on people, so improving their workflow boosts safety, speed, and precision. Automated systems offer real-time insight into staff performance and process efficiency. Managers can identify bottlenecks and refine workflows accordingly.

Automation also supports inventory flow and demand tracking. IT systems continuously assess product characteristics, locations, and quantities, allowing supply chains to remain agile and error-free.

Benefits of Warehouse Automation

Investing in automation yields long-term value and measurable gains:

- Stacker cranes can handle more loads simultaneously than forklifts.

- Vertical storage systems maximize space utilization.

- Machines reduce order errors and boost customer satisfaction.

- Automated systems maintain high productivity levels.

- Speedy order processing improves overall business efficiency.

- Heavy-duty automation improves warehouse safety.

- Vending reduces misuse and saves budget.

- It enables a “goods-to-person” model, cutting labor costs.

- Automation supports – not replaces – human workers (for maintenance, repairs, supervision).

Ultimately, the key benefit of Warehouse 4.0 is cost savings through higher performance and optimized potential.

FAQ:

Which warehouse processes can be automated?

Many: workforce coordination, goods transport, order fulfillment, and inventory tracking.

What are the main benefits?

Warehouse 4.0 expands your business capacity, increases profits, and optimizes space, safety, and accuracy.

How does automation affect workers?

It increases safety and introduces new roles (maintenance, programming, system oversight).

Are vending machines useful in logistics?

Yes. They’re excellent for distributing consumables, PPE, and tools, reducing misuse and optimizing costs.