Did you know that your products can be dispensed using the FIFO method?

Efficient sales and logistics are not only about having well-chosen products, their display, and presentation, but also about proper inventory management. The way products are rotated can impact a company’s profitability and service quality. This applies to both warehouses and vending machines. In this regard, it’s worth paying attention to the FIFO method. Find out the benefits of this feature and why it’s worth implementing in your machines.

What is the FIFO method?

FIFO (First In, First Out) is a principle where products placed in a warehouse, dispensing device, or vending machine first are also the first to be dispensed. In practice, this means that older items leave the machine or storage first. FIFO is the opposite of the LIFO method, where the newest products are dispensed first.

Using the FIFO method doesn’t require any additional work from the operator. In ASD Systems vending machines, this function can work automatically, just like the FEFO method (First Expired, First Out). FEFO ensures that products with the shortest remaining shelf life are dispensed first, preventing expiration or product stagnation.

Why should you implement FIFO in vending machines?

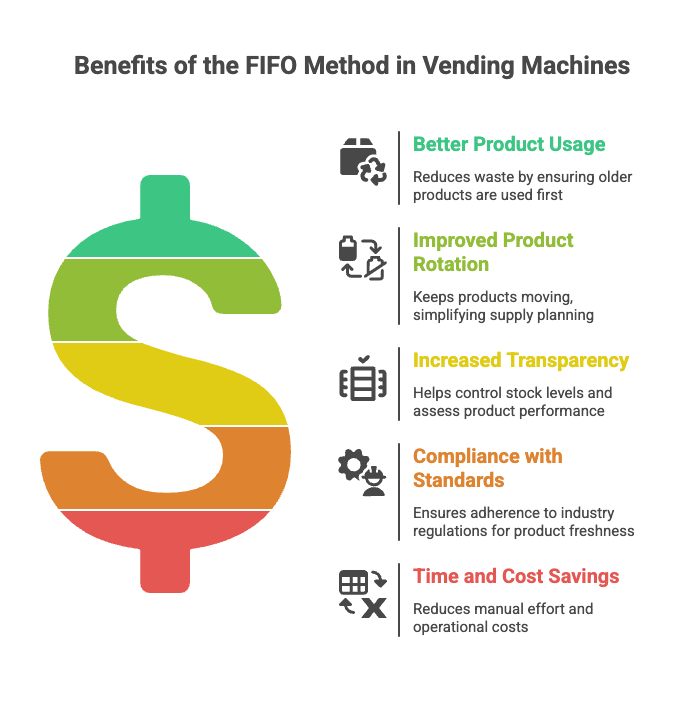

The FIFO method brings many benefits and savings, including:

- Better product usage and fewer losses – older batches don’t sit idle or expire, reducing the need to remove them from machines.

- Improved product rotation – items are constantly in motion, making supply planning easier.

- Increased transparency – analyzing product rotation with FIFO helps control stock levels and assess which products should stay in the offer and which should be replaced.

- Compliance with standards and regulations – in many industries, product freshness is mandatory. FIFO is particularly important in industrial and automotive sectors if the device is a vending machine.

For example, in a manufacturing company, a new batch of protective gloves is loaded into a vending machine each week. Thanks to FIFO, the gloves that were loaded the previous week are dispensed first. This prevents product expiration and waste.

In which industries is FIFO especially important?

FIFO is useful in almost every industry. For ASD Systems vending machines, it’s particularly relevant in dispensing PPE and MRO tools, where controlling product rotation is crucial for safety and process continuity. It is especially effective in industries such as:

- manufacturing,

- logistics,

- hospitals and laboratories,

- machining,

- welding,

- energy,

- automotive.

With FIFO, there’s no need to manually rearrange products by expiration date or constantly monitor their status. This saves time, reduces costs, and offers great convenience – especially when managing multiple devices across various locations.

If you already use ASD Systems vending machines and want to enable FIFO, contact your technical account manager. If you’d like to learn more about modern vending and bring innovative, fully functional machines into your business, get in touch with us.

Sign up for our newsletter!

Sign up and be the first to hear about new features, updates, and proven ways to save in warehouse management.