What is warehouse management?

Before a product reaches the customer, it spends time in a warehouse. Efficient management of this space is essential for the smooth operation of the entire company. Warehouse management defines the rules for receiving, storing, picking, moving, and recording goods. How to manage it well? Discover the warehouse management guide and optimize operations in your company.

Warehouse Management – Definition

According to the Online Management Encyclopedia, warehouse management is “a business activity focused on the proper storage of physical goods to ensure the continuous functioning of the company.” This brief definition covers a wide scope of logistics and inventory control practices.

To understand warehouse management more fully, it’s crucial to examine its goals and the role a warehouse plays in the organization. A better grasp of these aspects enables more effective inventory strategies, which directly impact business performance.

The primary goal of warehouse management is to ensure a steady flow of supplies to production, facilitate material handling, and manage the dispatch of finished goods. According to Z. Dudziński, author of the Warehouse Management Handbook, effective warehouse operations should achieve maximum results with minimal labor input.

Key Functions of Warehouse Management

Effective warehouse operations go far beyond simply storing goods. The core functions of warehouse and materials management include:

- goods receipt – receiving deliveries, quality and quantity inspection, and system registration,

- inventory storage – using inventory rotation systems like FIFO or LIFO,

- order picking – assembling goods according to documentation,

- product dispatch,

- inventory audits – tracking stock levels and maintaining accurate records,

- document archiving,

- space and inventory control – optimal use of space impacts daily warehouse efficiency,

- support for logistics processes – warehouse management is closely integrated with logistics, production, sales, and transport coordination.

Additionally, warehouse management must ensure workplace safety (compliance with PPE and HSE standards), protecting both employees and stored goods.

Efficient Warehouse Management – Essential, Not Optional

A well-functioning supply chain is one of the cornerstones of successful warehouse and enterprise management. Without it, order fulfillment fails, internal operations collapse, and staff cannot perform their duties efficiently. Supply chain performance, in turn, is shaped by the company’s logistics framework.

Proper warehouse logistics improve:

- company-wide organization,

- delivery lead times,

- accuracy of order fulfillment,

- costs related to handling physical inventory.

How to Manage Warehouse Operations – Logistics Principles

Warehouse management cannot exist without logistics. In essence, logistics aims to satisfy market demand with minimal financial input, covering every phase of material flow: procurement, production, and distribution.

Warehouse logistics includes all tasks related to the flow of goods through a warehouse. Efficient warehouse operations, based on logistics and economic principles, allow for:

- maintaining optimal stock levels to ensure production continuity without excessive storage costs,

- accelerating internal goods flow and interdepartmental operations,

- identifying savings opportunities,

- minimizing order errors and improving customer service,

- fast and reliable shipping of finished products,

- managing stable workforce costs.

Warehouse and inventory management is a multifaceted process that benefits warehouses, employees, and the entire business.

Warehouse Management vs. Materials Management – Key Differences

Although often used interchangeably, materials management and warehouse management cover different scopes:

- Materials management deals with the full material lifecycle: stock planning, purchasing, supplier relations, MRP, and collaboration with production.

- Warehouse management focuses specifically on storage and warehouse-related operations such as receiving, storing, order picking, and stocktaking.

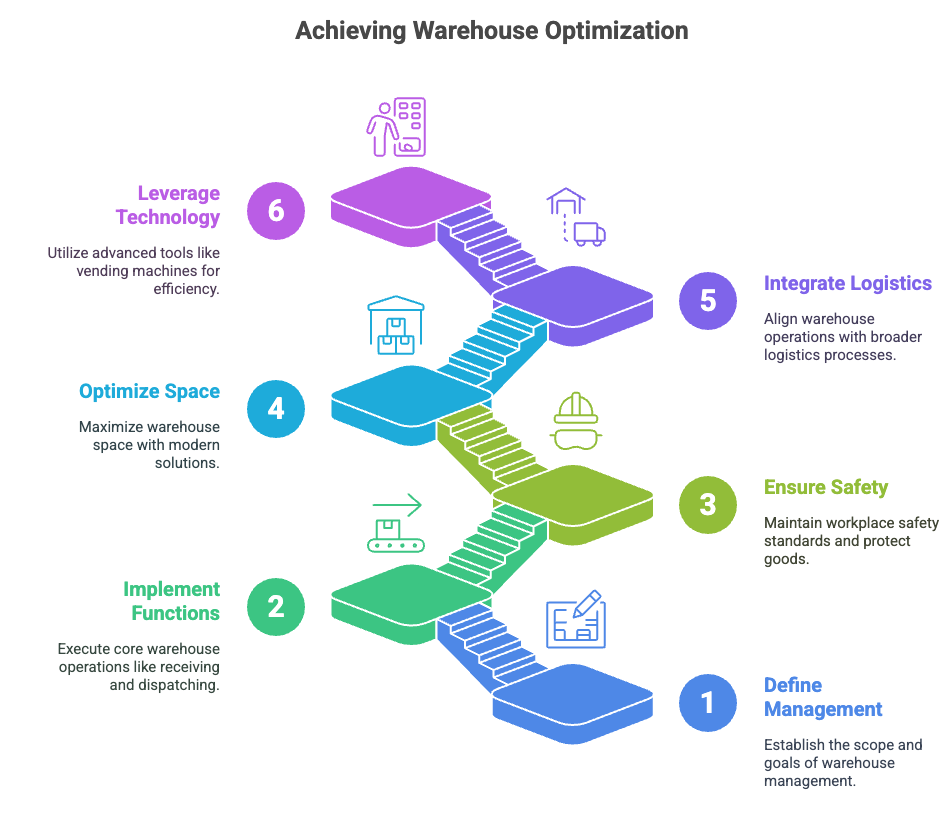

Key Areas of Warehouse Optimization

To ensure optimal warehouse performance, logistics must address three key areas:

- procurement – receiving and storing materials for production,

- production – distributing materials to production units,

- distribution – storing, assembling, and dispatching finished goods.

While specific practices vary depending on the business profile and types of stored materials, some universal principles include:

- maintaining appropriate stock levels,

- implementing modern tools and technologies,

- reducing transportation costs,

- maximizing warehouse storage capacity,

- timely and accurate order fulfillment,

- strategic warehouse zoning,

- leveraging advanced warehouse infrastructure: WMS software, barcode scanners, packaging machines, internal transport (e.g., forklifts), and more.

Warehouse Space Optimization

A warehouse cannot function without a well-designed physical space. Efficient warehouse layout planning ensures optimal use of every square meter, balancing storage needs with operating costs.

Modern infrastructure offers multiple solutions for maximizing space:

- mezzanines,

- work platforms,

- high-bay racking systems,

- mobile and sliding racks.

Internal transport solutions (e.g., forklifts with compatible pallets) require clearly marked and well-organized transport routes within the warehouse.

Modern Warehouse Management Solutions

As logistics evolves, so does warehouse management. Today, advanced tools and technologies enhance the way goods are stored, tracked, and distributed. One such innovation is the industrial vending machine.

Warehouse vending machines automate the distribution of:

- personal protective equipment (PPE) – masks, gloves, helmets, goggles, fall protection,

- workwear,

- tools – often referred to as smart tool cribs,

- consumables and MRO items.

These systems provide full visibility and control. All product data, stock levels, and usage patterns are tracked in real time via integrated software. Administrators can configure access rights, generate automated reports, and plan purchasing more efficiently.

Vending machines help prevent misuse, reduce downtime, and enhance overall warehouse efficiency. Case studies show that automated PPE and tool vending solutions lead to:

- reduced procurement costs,

- improved availability of critical items,

- better warehouse space utilization,

- minimized shrinkage and human error.